How to Calculate Predetermined Overhead Rate?

Based on this calculation, the business can make several decisions such as what the price of the product should be, how much resources should be allocated towards the production of the product, etc. If the predetermined overhead rate calculated is nowhere close to being accurate, the decisions based on this rate will definitely be inaccurate, too. That is, if the predetermined overhead rate turns out to be inaccurate and the sales and production decisions are made based on this rate, then the decisions will be faulty. When there is a big difference between the actual and estimated overheads, unexpected expenses will definitely be incurred. Also, profits will be affected when sales and production decisions are based on an inaccurate overhead rate.

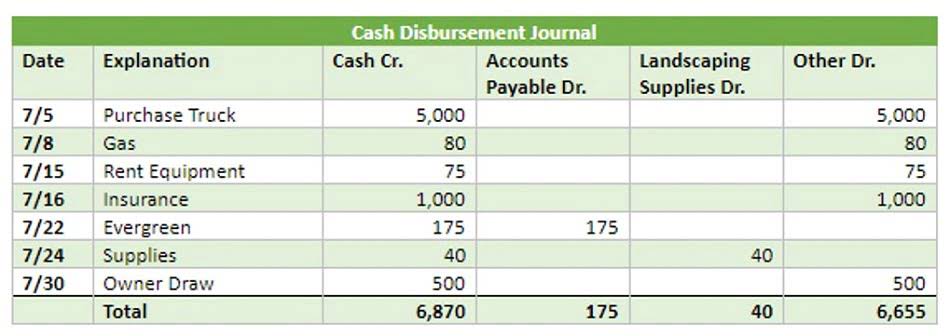

Estimated Total Manufacturing Overhead Costs

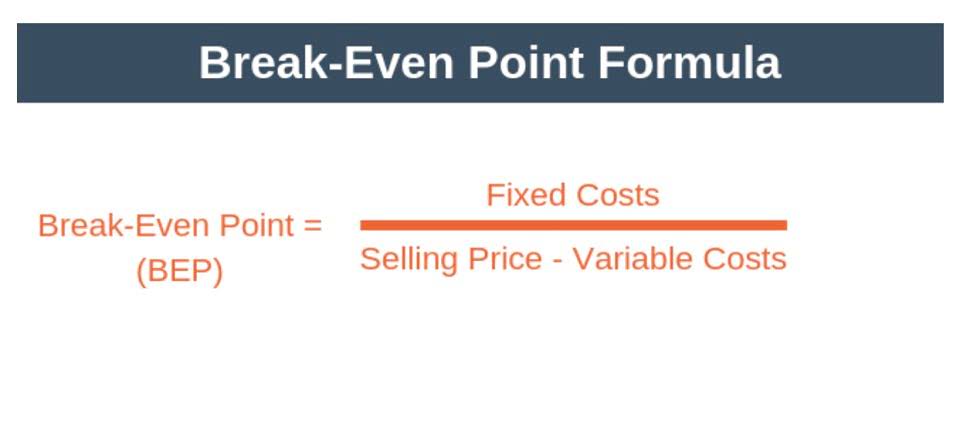

Hence, it is essential to use rates that determine how much of the overhead costs are applied to each unit of production output. This is why a predetermined overhead rate is computed to allocate the overhead costs to the production output in order to determine a cost for a product. The predetermined overhead rate is, therefore, usually used for contract bidding, product pricing, and allocation of resources within a company, based on each department’s utilization of resources. A predetermined overhead rate is an estimated amount of overhead costs that will be incurred during a set period of time. This rate is used to allocate or apply overhead costs to products or services.

What are some examples of overhead costs?

Finally, using a predetermined overhead rate can result in inaccurate decision-making if Bookstime the rate is significantly different from the actual overhead cost. Similarly, as mentioned above some businesses may use it as a monitoring and control tool. If the predetermined overhead rates are not accurate, they can force the business to control its activities according to unrealistic rates.

Our Services

For example, let’s say the marketing agency quotes a client $1,000 for a project that will take 10 hours of work. The agency knows from its predetermined overhead rate that it will incur $200 in overhead costs for the project. A predetermined overhead rate is an allocation rate given for indirect manufacturing costs that are involved in the production of a product (or several products). Predetermining is a process of working out the predetermined overhead rate by dividing the estimated amount of overhead by the estimated value of the base before actual production commences. However, estimating does not involve predicting or forecasting instead it only involves quantifying for an interval of time.

- So, if you were to measure the total direct labor cost for the week, the denominator would be the total weekly cost of direct labor for production that week.

- This means that for every dollar of direct labor cost a production process uses, it will use $1.50 of overhead costs.

- Direct costs typically are direct labor, direct machine costs, or direct material costs—all expressed in dollar amounts.

- It would involve calculating a known cost (like Labor cost) and then applying an overhead rate (which was predetermined) to this to project an unknown cost (which is the overhead amount).

- Figure 4.18 shows the monthly manufacturing actual overhead recorded by Dinosaur Vinyl.

The computation of the overhead cost per unit for all of the products is shown in Figure 6.4. It is often difficult to assess precisely the amount of overhead costs that should be attributed to each production process. Costs must thus predetermined overhead rate be estimated based on an overhead rate for each cost driver or activity.

- As explained previously, the overhead is allocated to the individual jobs at the predetermined overhead rate of $2.50 per direct labor dollar when the jobs are complete.

- Based on the manufacturing process, it is also easy to determine the direct labor cost.

- If you’d like to learn more about calculating rates, check out our in-depth interview with Madison Boehm.

- Another way to view it is overhead costs are those production costs that are not categorized as direct materials or direct labor.

- Nonetheless, ignoring overhead costs, like utilities, rent, and administrative expenses that indirectly contribute to the production process of these gadgets, would result in underestimating the cost of each gadget.

- If the predetermined overhead rates are not accurate, they can force the business to control its activities according to unrealistic rates.

- Also, if the rates determined are nowhere close to being accurate, the decisions based on those rates will be inaccurate, too.

- He currently researches and teaches economic sociology and the social studies of finance at the Hebrew University in Jerusalem.

- The agency knows from its predetermined overhead rate that it will incur $200 in overhead costs for the project.

- Once a company determines the overhead rate, it determines the overhead rate per unit and adds the overhead per unit cost to the direct material and direct labor costs for the product to find the total cost.

- This activity base is often direct labor hours, direct labor costs, or machine hours.

In this article, we will cover how to calculate the predetermined overhead rate. The predetermined overhead rate is also commonly called predetermined absorption rate or predetermined overhead absorption rate. Before jumping to detail, let’s go through the basic overview and key definition first.

Again, this predetermined overhead rate can also be used normal balance to help the business owner estimate their margin on a product. This predetermined overhead rate can also be used to help the marketing agency estimate its margin on a project. This predetermined overhead rate can be used to help the marketing agency price its services. Once you have a handle on your estimated overhead costs, you can plug these numbers into the formula. Company B wants a predetermined rate for a new product that it will be launching soon.

![Daniël Klijn [LittleDean]](http://www.littledean.nl/wp-content/uploads/2018/10/cropped-Littledean-LONG-wit-1-1-1.png)